AGUAR WATER TECHNOLOGIES LLP

Boiler Water Treatment Chemicals

A complete water treatment programme for a steam boiler will usually include a chemical oxygen scavenger, alkalinity builder and polymer sludge conditioner and, depending on the application, may also incorporate a phosphate treatment and a condensate line treatment.

• Oxygen Scavengers: a chemical oxygen scavenger is used to remove the residual oxygen from the boiler feed water in order to protect the boiler.

• Alkalinity Builders: depending on the natural feed water alkalinity, it is often necessary to add an alkalinity builder in order to establish the correct boiler water chemistry to prevent corrosion and scale formation.

• Sludge Conditioners:a polymer sludge conditioner should always be used to ensure that any hard water that enters the boiler doesn’t result in scale, by ensuring that the precipitated hardness is converted to a mobile sludge which can be removed by blowdown.

• Boiler Phosphate Treatment Chemicals: phosphate treatments are used in low pressure boilers to help prevent scale formation and in high pressure boilers as pH control agents.

• Steam Condensate Line Treatment Chemicals: when steam condenses, it can absorb oxygen and carbon dioxide which can cause rapid and costly corrosion of the condensate return lines.

Cooling Water Treatment Chemicals

Cooling tower water-related problems can be generally classified in four different categories: corrosion, scaling, fouling, or biological activity.

• Regular Treatment: Scale and corrosion inhibitor is a multifunctional scale and corrosion inhibitor for cooling water systems. It is a synergistic blend of advanced polymers for mineral scale inhibition, dispersant for silt, suspended matter and corrosion inhibitor for protection against scale, corrosion and fouling.

• Microbial control program: Bio-dispersant use in along with chlorination and/or non-oxidizing biocides to improve the performance of systems fouled with microbiological slime by removing and dispersing these deposits.

• Non-oxidizing biocide:Non-oxidizing biocide is a broad spectrum non-oxidizing biocide for cooling water systems. Biocide is excellent to control aerobic and anaerobic microorganisms in cooling water system.

• Oxidizing Chemicals: Oxidizing Chemicals in cooling tower use to kill the microorganism. Free residual chlorine (FRC) indicates the presence free residual chlorine after satisfying the chlorine demand of water.

Coagulant and Flocculant for water and wastewater treatment

Specialized Coagulants

• Cationic coagulants are used for emulsion breaking, promoting filtration and sludge dewatering.

• As a primary organic coagulant, it neutralizes negatively charged colloidal particles and thus induces flocculation and sedimentation which reduces sludge volume.

• The product is particularly suitable for high biological content, or other difficult to treat substrates, like industrial effluent and for colloidal particle removal.

• Potable water grade coagulant for clarification and filtration of potable water and for conditioning of potable water

Polyelectrolytes

• Polymer is often used to bind suspended solids in wastewater and allow them to settle. Using polymer makes the wastewater clearer and it can be reused or discharged.

• There are two types of polyelectrolytes as cationic polyelectrolytes and anionic polyelectrolytes

• Cationic poly majorly used in industrial and municipal solid liquid separations (sludge dewatering application). Polyacrylamide-based flocculants highly effective across mechanical sludge dewatering and sludge thickening, suspended settling.

• Anionic poly used for post-coagulation as flocculating agent for a wide range of industrial effluent applications.

• Specialty Flocculant as Defoamer - provide efficient and durable foam control in the waste water treatment applications.

Wastewater Bioprocess Solution and Microbial Culture

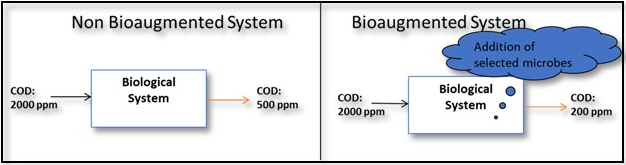

In the aeration basin of an ETP/STP a biomass develops based on numerous strains of degradative and floc forming bacteria. This diversity of bacteria is necessary because different strains of bacteria are more effective in degrading different organic compounds. The biomass becomes adapted to the influent and will provide the required results provided a steady state of operation can be maintained. This is virtually impossible in an industrial plant where the influent characteristics can change drastically on a daily, or even hourly, basis.

• For an effective treatment, commercially formulated microbial products need to be added to increase or restore the degradation process. Selectively introduced organisms are better suited for conditions e.g. temperature, pH, salinity, etc.

• With bioremediation, enhancing the positive characteristics of the biomass and suppressing the more negative characteristics. It does not involve the total replacement of the existing biomass

• AguBacproducts are high potency, bacteria-laden formulation for use in degrading recalcitrant organic compounds in industrial wastewaters.

• AguBac MN100is a water soluble formulation containing magnesium, iron, zinc, molybdenum, calcium, cobalt and copper. It helps to in improving oxygen supply to the bacteria and improve treatment efficiency. Benefits also include improved effluent quality, including BOD, TSS, NH3, P and turbidity.